Warehouse operations that run like clockwork. Perfectly stocked, tracked, and delivered inventory, and customers who can’t stop raving about your efficiency and delivery times—that is the ultimate goal! Can IoT in warehouse management help attain this level of efficiency? Let’s find out!

Providing efficient, smart, and sustainable warehouse solutions is possible. All you need is the right technologies. IoT is steadily revolutionizing warehouse management by connecting devices, machinery, and inventory. It’s helping leading businesses globally drive efficiency, reduce costs, and transform operations in real time.

Here’s more on how IoT solutions for warehouse management tackle common challenges and improve business performance.

Build Smart WMS Solutions That Caters To Your Specific Warehouse Management Challenges

What is the IoT in Warehouse Management?

The Internet of Things is a network of electronic gadgets embedded with technology. IoT enables them to connect and exchange data over the internet. These devices can collect and share data, communicate with each other, and be controlled remotely.

The Internet of Things (IoT) is a viable solution to enhancing efficiency in various industries. IoT in Warehouse Management can help perform a wide range of tasks. It can perfect tasks from monitoring inventory levels to optimizing workflow and providing real-time insights. It can revolutionize processes using basic automation to high-grade predictive analysis.

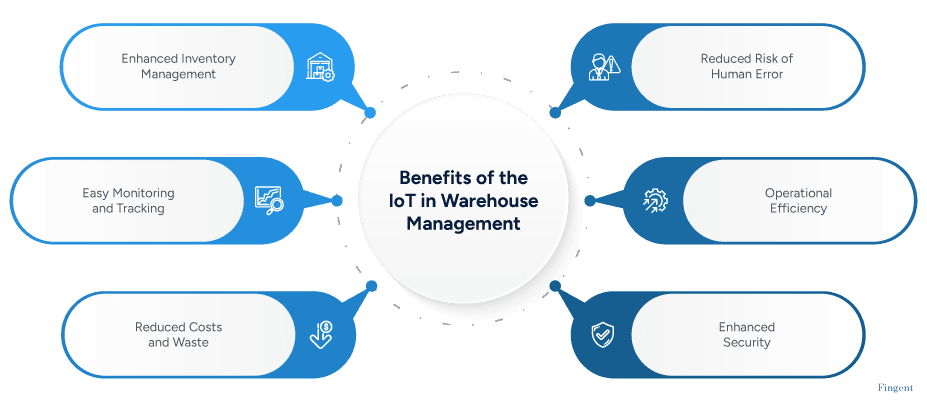

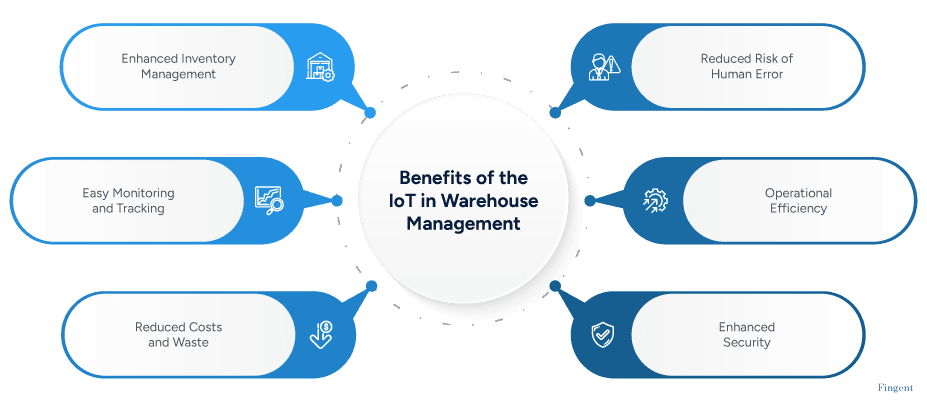

Benefits of the IoT in Warehouse Management

The industry’s growth rate shows that businesses are reaping the benefits of IoT in warehouse management. It is projected to grow at a CAGR of 13.1% from 2023 to 2030 and be worth USD 28.79 billion by 2030!

IoT-based warehouses, also known as smart warehouses, are making a notable difference. The IoT has plenty to offer, showing benefits ranging from increasing efficiency to cutting costs:

1. Smart Shelves: Enhanced Inventory Management

IoTfor inventory management enables comprehensive data analytics to check inventory levels. IoT-embedded shelves detect low inventory levels and send immediate restocking alerts. This ensures that stock levels are maintained efficiently.

IoT provides precise tracking of assets to cut the time to locate products. It also gives accurate insights into inventory flow management. These strategic decisions about stock replenishment and resource allocation can transform your warehouse.

2. All Eyes on Deck: Monitoring and Tracking

With Bluetooth connectivity, IoT can offer real-time monitoring and operation tracking. IoT sensors integrated inside inventory articles provide real-time updates to warehouse managers. They track product status, movements, and location. It also provides real-time data analysis and intelligent insights to optimize processes further.

IoT-based security cameras and sensors can oversee inventory shelves and storage areas. This ensures timely intervention and reduces the risk of stockouts or overstock. Real-time visibility can save resources, reduce waste, and prevent spoilage.

3. Waste Not Want Not: Reduced Costs and Waste.

IoT-enabled predictive maintenance systems can detect equipment malfunctions and send timely alerts to warehouse managers about proactive repairs, mitigating risks, and downtime. The IoT also enhances warehouse sustainability. With smart lighting and climate control systems, warehouses can reduce the energy they consume.

4. On Guard: Enhanced Security

With IoT sensors, warehouse managers can oversee asset movement and environmental conditions. This mitigates the risk of theft and accidents while ensuring product integrity. These sensors are designed to gather data and send real-time alerts, enabling swift and effective action.

5. Reduced Risk of Human Error: Operational Efficiency

The biggest benefit of implementing IoT is the removal of human error. This can exponentially increase operational efficiency. Automated systems can perform mundane tasks and lower the chances of mistakes. Hence, freeing employees to work on complex aspects of the warehouse.

Seamless integration of smart devices and sensors can streamline workflow and boost productivity. These devices can also communicate with each other in real-time. Automated guided vehicles (AGVs) and telematics reduce the need for manual intervention. Thus, boosting logistics processes’ speed and accuracy.

Elevate Your Warehouse Management Efficiency With New-age Technologies

Common Challenges of Implementing IoT in Warehouse Management and Ways to Overcome Them

IoT in warehouse management is a powerful tool that will be invaluable, there’s no doubt about that. What do you do to ensure that this tool works for you? The first step is to recognize and overcome the challenges that come with IoT in warehouse management.

1. Data Integration and Management

Challenge: Most organizations have diverse data streams. Integrating these databases without any complications can be challenging.

Solution: A comprehensive data management platform can resolve this problem. The platform can unify and normalize data for analysis. Ensure that clear data management policies are laid out to evade security risks.

2. Legacy System Integration

Challenge: This is the most common challenge among various industries implementing IoT. Many businesses have a legacy system that does not support IoT in warehouse management, further complicating the integration process.

Solution: An effective way to mitigate this issue is to use APIs and middleware solutions. They will provide seamless data exchange between IoT devices and legacy systems.

3. Interoperability

Challenge: Buying devices from different vendors can create problems, and seamless communication between these devices can be challenging.

Solution: Adhere to open standards and protocols when adopting an IoT solution. Conduct thorough testing before deployment to identify and address interoperability issues.

4. Cost Considerations

Challenge: Although IoT can help you save money in the long run, its initial implementation can be expensive. Ongoing maintenance of sensor networks, devices, and infrastructure can also be a cost.

Solution: The best way to address this challenge is to brace for impact. Before implementation, conduct a thorough cost-benefit analysis to note potential ROI. Browse through various rollouts or cloud-based solutions to manage costs effectively.

5. Data Security

Challenge: Most business owners are increasingly concerned about the security of their data integrity. Trusting a new solution based on the Internet can be daunting, especially regarding sensitive inventory and operations information.

Solution: Conduct a comprehensive background check on your service provider before employing them. Once the solution has been deployed, regular risk assessments will be conducted. Employee training in cybersecurity is also important. Your cybersecurity measures must include encryption and regular patching.

6. Change Management

Challenge: Change is inevitable, but that doesn’t exempt it from being condemned by many. Successful IoT implementation will require full support from the warehouse staff. This can be challenging, as some employees may not be tech-savvy.

Solution: Education is key. The best way to ensure a successful implementation is through open communication. Express the benefits of IoT solutions for warehouse management and highlight how they will enhance productivity and security. Provide adequate training to all employees in IoT technology, software, and processes. Begin with small-scale pilot projects before implementing full-scale rollouts.

How Does Amazon Use IoT in Warehouse Management?

Unsurprisingly, the world’s largest retail business uses IoT in its warehouse management system. Amazon uses sensors, and it is commonplace to see robots manage tasks like packing, stocking, and tracking. It has used automated guided vehicles to transport products within the warehouse for over a decade. Here are some other ways Amazon uses IoT in its warehouse:

- Robots: Amazon uses 100,000 robots to move and group stock, taking shelves with items to the picking and packing zone and then moving them to the storage area. This helps to create efficiencies in order fulfillment and eliminate the physical rigors of an otherwise physically demanding job.

- RFID tags: These tags are attached to products. Radio waves communicate data about the product to a central system. The data includes information about the asset’s location, type, and quantity. This allows warehouse managers to track the asset without relying on manual input from staff.

- Connected wristbands: Amazon is considering using connected wristbands on a whole new level. Ultrasonic tracking can detect a worker’s location. A haptic feedback system takes it a step further. Vibrations will nudge the worker’s hand in the right direction. Imagine the reduction in response time this would mean!

Some Frequently Asked Questions Around the Use of IoT in Warehouse Efficiency

1. How does the IoT transform warehouse management?

IoT in warehouse management can enhance operational efficiency. It provides seamless integration of smart devices and sensors, which streamlines workflow. Thus, it enhances overall productivity and reduces the risk of human error.

2. What IoT sensors can be used in the warehouse?

The IoT sensors that are usually used in warehouses are:

- Sensors to Locate and track products

- Traffic light systems to reduce clashes and damage

- Dock and door motion monitors

- Sensors to prevent corner collisions

- Sensors to send alerts when stock is low

3. How can IoT improve the logistics process?

IoT in warehouse management can improve logistics processes through real-time tracking. It enables a dynamic real-time monitoring of shipments and assets, enhancing route management and delivery accuracy.

4. What are the benefits of IoT in logistics and warehouse management?

The benefits of implementing the IoT in warehouse management are multifaceted. They range from a streamlined flow of goods and reduced errors to increased visibility in inventory levels.

5. What industries benefit most from IoT in warehouse management?

Retail, e-commerce, manufacturing, logistics, pharmaceuticals, and the food and beverage industries benefit the most from IoT in warehouse management. These industries tend to have complicated supply chains and large inventories. Hence, IoT can provide the greatest efficiency, accuracy, and cost savings advantage.

Reduce Labor Costs With Warehouse Automation

How Can Fingent Help Bring Warehouse Efficiency to New-Age Technology?

Implementing the IoT in warehouse management requires a deep knowledge of the technology and an innate sense of how it can work for your business. Fingent is a service provider with clients across the world. We offer vast and extensive experience in delivering highly intuitive applications and solutions. Our experts can add immense value to your strategy and make seamless deployments. We can make your processes efficient, cut excessive costs, and unlock hidden potential.

We understand the need to implement the latest advancements in warehouse management systems. A case in point is the web-based solution that we recently provided for one of our clients in Australia. The solution helped the client to track, control, and efficiently manage deliveries. This resulted in

- 43% increase in customer base

- 50% reduction of internal workload.

Fingent has helped leading businesses create product ordering systems, e-commerce applications, and more to enable optimized operations. We help organizations adopt cutting-edge technology while gradually replacing legacy systems, enabling them a competitive edge!

Take customer satisfaction to another level with us! Contact us now!

[ad_2]

Source link